Polyethylene VS cellophane

Polyethylene VS cellophane

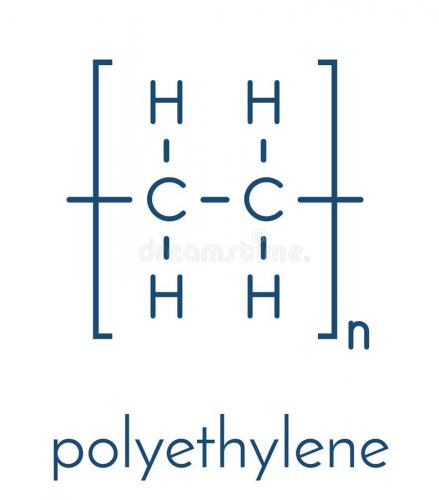

Despite the fact that the two types of material are similar in appearance (have a transparent color and crunch when compressed), the difference between them is very great. And it begins from the very moment of its creation: cellophane is a natural material, and polyethylene is an artificial material. Cellophane is a transparent transparent film resistant to water and various odors. Such a package is obtained in the processing of pulp, the raw material for which is wood. Polyethylene is produced by chemical synthesis of ethylene hydrocarbon gas.

The active use of cheap polyethylene since the 1950s has gradually supplanted its older comrade. Nowadays, most often cellophane can be found as a candy wrapper, on a cigarette pack, and as gifts. Such limited use of plastic packaging is associated with its time-consuming and costly production. But for the global ecology, such a package is less dangerous, because it is inherently a natural material and capable of safe decay. But available are not amenable to natural decomposition, which cause great harm, polluting the environment.

Polyethylene, Polypropylene and Cellophane are the most used materials in the craft sector. Polypropylene and polyethylene are two polymers for the manufacture of various plastic products. At first glance they may look like similar materials but, in reality, the differences between them are remarkable. Polyethylene is the most widespread material, while the use of polypropylene is more specific.

Polyethylene is present in many of the products that surround us, with different chemical components you can get a resistance and durability that makes it very versatile in the manufacture of plastic products, its density is an important factor to obtain different uses or products.

The idea is that you know how to differentiate them, to choose the product that best suits your project or creative idea.

Polyethylene or Polyethylene is a well-known thermoplastic it is the base of the most used plastic in the world, which is characterized by being a stable, resistant material with no toxicity. In addition, it can be molded, extruded or blown in virtually any way.

Polyethylene resists low temperatures without losing its characteristics. It is a very elastic material and with a high flexibility, it stretches easily. The polyethylene plates give rise to a more rigid type of plastic, with a great resistance to shocks, impacts and wear.

Being resistant to solvents and being a low cost element, its application is perfect for packaging, protection of objects, transportation, crafts, etc. One of the most widespread uses of this plastic material is in protective packaging.

The plastic made with white polyethylene is very versatile, giving rise to very different products for packaging and protection. There are many commercialized products that we find with this chemical product, for example the well-known bubble film, polyethylene plates for protection, spongy plates that help cushion possible blows during the transport of goods.

Settings

Tags

cellophane Polyethylene cellophane wrap cellophane bags cellophane fka twigs polyethylene glycol 3350 polyethylene glycol uses polyethylene glycol side effects polyethylene terephthalate polyethylene plastic polyethylene glycol brand name polyethylene foam polyethylene glycol in food polyethylene armor polyethylene adhesive polyethylene and polypropylene polypropylene polyethylene glycol polyethylene bags nylon polythene sheet b&q

cellophane Polyethylene cellophane wrap cellophane bags cellophane fka twigs polyethylene glycol 3350 polyethylene glycol uses polyethylene glycol side effects polyethylene terephthalate polyethylene plastic polyethylene glycol brand name polyethylene foam polyethylene glycol in food polyethylene armor polyethylene adhesive polyethylene and polypropylene polypropylene polyethylene glycol polyethylene bags nylon polythene sheet b&q