Cellophane and polypropylene

Cellophane and polypropylene are both used to package food and other products. As a food packaging, cellophane is easier to manipulate and costs more than polypropylene. Both products are approved by the U.S. Food and Drug Administration.

Cellophane

Cellophane is a paper product made from wood pulp. It was invented in 1900 and has been continuously manufactured since the 1930s. Cellophane allows moisture to pass through, preventing condensation. In addition to food packaging, cellophane is used to wrap flowers and gifts, and to make adhesive tape.

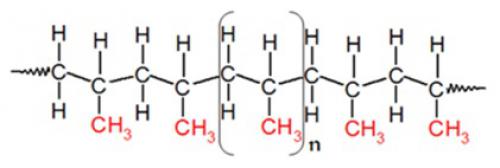

Polypropylene

Polypropylene is a thermoplastic polymer derived from crude oil. It is used to make plastic products such as packaging containers; wrap for food and other products; and fiber products including carpet, rope and clothing. Polypropylene is stronger than cellophane but must be heat-sealed or taped to close.

Environmental Considerations

Cellophane is made from plants so is biodegradable, however toxic chemicals including carbon disulfide and sulfuric acid are used in the manufacturing process. Polypropylene is a petroleum-based product that does not readily break down. Plastics can be recycled, though separating the component chemicals is not easy, and different types of plastic must be sorted before recycling.

Plastic is one of the most abundant materials available today. Plastic can be found in bags, bottles, cups, plates and more. It may seem fairly generic, but there are actually seven different levels of plastics. The resin identification codes were voluntarily developed in 1988 by SPI, the Plastics Industry Trade Organization. These levels become especially important during recycling because each type of plastic requires specific recycling practices. The American Chemistry Council has published a chart outlining each of the seven levels, making the confusing topic easier to understand. Levels are indicated on the bottom of all products inside a triangle. This system was implemented by manufacturers to make recycling simple.

Level 1

plastics are denoted by a number 1 inside the common triangle, with the letters PET below. PET stands for polyethylene terephthalate. This type of plastic is clear and tough and is a good barrier for gas and moisture. Type 1 plastic is commonly found in beverage bottles, mouthwash bottles, food jars and microwavable containers. An article written by John Holusha in the New York Times notes this type of plastic as being the most commonly recycled. Holusha also mentions that PET is commonly reused in applications such as carpeting or fiberfill for sleeping bags.

Level 2

plastics are indicated by the traditional triangle with a number 2 inside and the letters HDPE below. HDPE indicates high density polyethylene. This type of plastic is used in a wide variety of products including milk jugs, cosmetics, household cleaners, shopping bags and the liners found in cereal boxes. HDPE is very chemical resistant, which makes it an excellent option for the packaging of many of these products. The New York Times reported that type 2 plastics are commonly recycled as well, although clear forms are more valuable and easier to recycle. Colored packaging, although made from type 2 plastic, is more limited in its reuse.

Level 3

inside the triangle with the letters PVC below denote a level 3 plastic. PVC stands for polyvinyl chloride. PVC is a very common form of plastic used in pipe, siding, fences, medical tubing and plastic wrap for deli meats. The plastic has the unique ability to be incorporated into both rigid and flexible products, which makes it an excellent choice for many products.

Level 4

plastics are indicated by a number 4 inside the traditional triangle with the letters LDPE below. LDPE stands for low density polyethylene. LDPE is both tough and flexible, making it a great option for materials that require both of these properties. Popular products that are made from LDPE include squeezable condiment containers, toys, garbage bags, and container lids. Linear low density polyethylene plastics, known as LLDPE, also are included in this category.

Level 5

Plastics falling into this category will have the number 5 enclosed in the recycling triangle and the letters PP below. PP stands for polypropylene. This is a very common type of plastic found in products that many people use on a regular basis. This plastic has an especially high melting point, which makes it beneficial for hot-fill liquid containers. It is often used in the manufacturing of caps and closures for bottles, yogurt and butter containers, and takeout plates.

Level 6

A plastic with a number 6 inside the triangle and the letters PS below will fall into this category. PS indicates polystyrene. This is another versatile plastic that can be both rigid and foamed. In its general purpose form, this plastic is clear, hard and brittle, and has a relatively low melting point. This plastic is often found in food service items, takeout containers, packing peanuts and meat trays. According to the New York Times, this type of plastic is less desirable for recyclers because it is more than 90 percent air.

Level 7

This final level of plastic is denoted by the number seven inside the traditional triangle with the word OTHER below. This category is reserved for packages that are made with a resin other than the previous six or is made with a combination of resins. Common items that fall into this category are large 3 to 5 gallon reusable water bottles, oven-baking bags and custom packaging.

Settings

Tags

Cellophane and polypropylene polypropylene Cellophane atlanta cellophane and polypropylene cellophane polypropylene difference between cellophane and polypropylene bags cellophane vs polypropylene bags difference between cellophane and polypropylene is polypropylene the same as cellophane are cellophane bags food safe what is a cellophane bag cellophane or polypropylene what is the difference between cellophane and polypropylene is cellophane better than plastic cellophane vs polypropylene cellophane wrap cellophane bags cellophane tape cellophane meaning cellophane definition polypropylene fabric polypropylene rugs polypropylene plastic polypropylene glycol polypropylene sheet polypropylene bags polypropylene abbreviation polypropylene adhesive cellophane paper cellophane art cellophane amazon cellophane synonym cellophane alternative cellophane synonym cellophane bags for cookies cellophane a hamper

Cellophane and polypropylene polypropylene Cellophane atlanta cellophane and polypropylene cellophane polypropylene difference between cellophane and polypropylene bags cellophane vs polypropylene bags difference between cellophane and polypropylene is polypropylene the same as cellophane are cellophane bags food safe what is a cellophane bag cellophane or polypropylene what is the difference between cellophane and polypropylene is cellophane better than plastic cellophane vs polypropylene cellophane wrap cellophane bags cellophane tape cellophane meaning cellophane definition polypropylene fabric polypropylene rugs polypropylene plastic polypropylene glycol polypropylene sheet polypropylene bags polypropylene abbreviation polypropylene adhesive cellophane paper cellophane art cellophane amazon cellophane synonym cellophane alternative cellophane synonym cellophane bags for cookies cellophane a hamper